The Sprayable Lubricant LGL

The Sprayable Lubricant LGL

LGL is a sprayable lubricant which is recommended for the lubrication of blank and blow moulds in the hollow glass industry. Optimized for sprayable application, it is possible to produce very thin and defined layers on the mould. It is recommended to use LGL with XPAR Vision's BlankRobot system. The active ingredients, which consists of components containing aluminium, protect the moulds and ensure a long-lasting layer. The finishing of the glass surface with aluminium additionally ensures a higher breaking strength of the manufactured glass. It is offered for all types of container glass production (blow-blow, press-blow and NNPB processes).

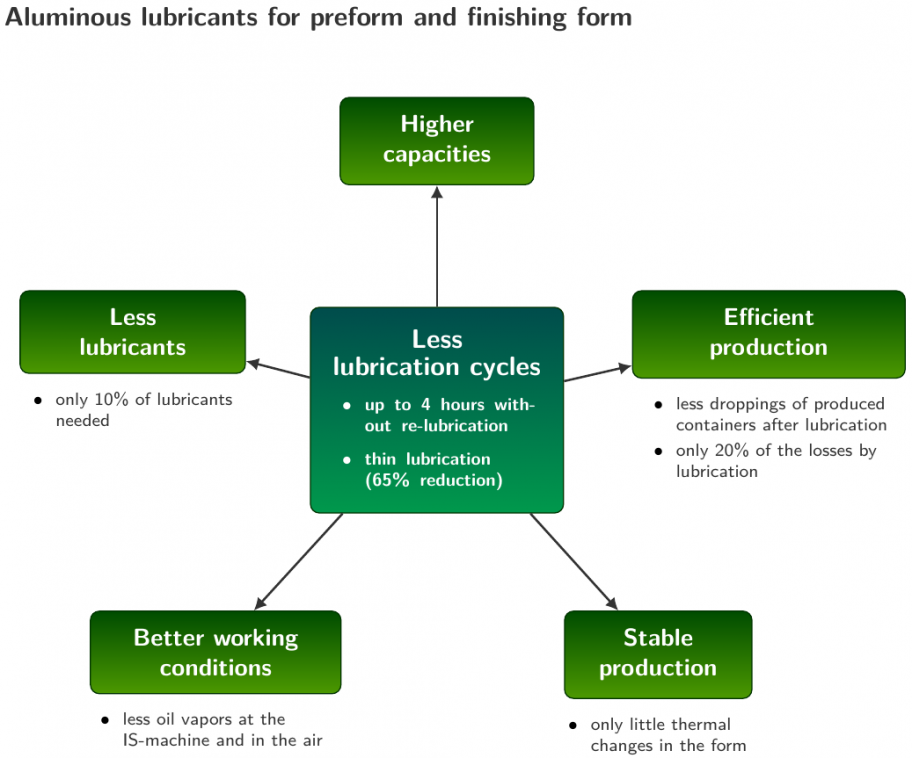

LGL has the following advantages:

- Semi-liquid sprayable therefore definable swabbing compound

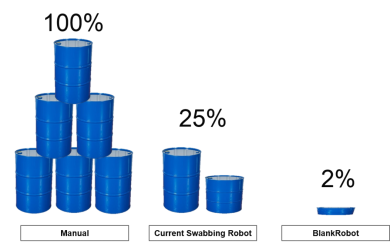

- Lower consumption of lubricant in comparison to other products

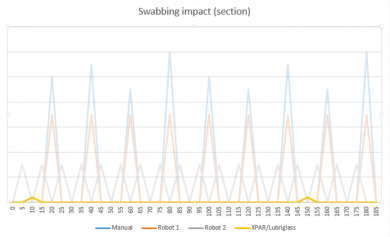

- Very long-lasting effect, extended time intervals between swabbing operations up to 3 hours

- Aluminium containing active ingredients protect moulds and increase the breaking strength of the manufactured glass

- No glass staining when properly applied on moulds

- No influence on the colour or tint of the glass

- Excellent loading and releasing properties

- Cleaner moulds and cleaner equipment

- Less residue build up in the moulds and cleaner machine environment, thus reducing maintenance costs, mould changes as well as operator interventions